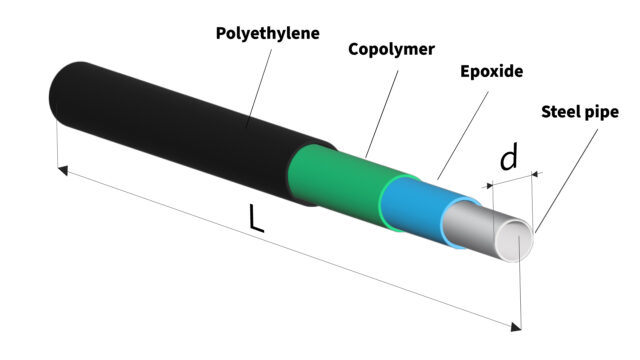

We can supply all steel pipes with an external polyethylene or polypropylene anti-corrosion coating. The insulation of steel pipes with protective coatings is performed at the production plant in Prakovce (Slovakia).

3LPE and 3LPP insulation is applied to steel pipes with a diameter of ø114.3 mm to ø1422 mm and a length of 8 m to 16 meters. The production of coatings complies with the PN-EN ISO 21809-1 or DIN 30670 and DIN 30678 standards.

The isolation process consists of the following steps:

• shot-blasting of the steel pipe surface to the cleanliness class Sa 2 1/2 according to PNEN ISO 8501-1: 2008,

• induction heating of pipes to a temperature of 180-200 °C,

• electrostatic spraying of epoxy powder on heated pipes,

• electrostatic spraying of polyethylene or polypropylene copolymer powder,

• spiral-circumferential extrusion of a layer of polyethylene or polypropylene,

• insulation cooling with water jets,

• mechanical processing of pipe ends,

• temporary protection of pipe ends with anti-corrosion varnish.

3LPE / 3LPP three-layer extruded anti-corrosion coatings are characterized by:

• high mechanical and strength resistance in relation to other types of insulation, eg in the form of polyethylene tapes,

• resistance to chemical agents, humidity, electric breakdown, high temperatures and ultraviolet rays, • high adhesion of the coating to the pipe,

• guaranteed long-term corrosion protection of pipelines working underground (for about 50 years), • complete protection of welds and the weld zone of insulated welded pipes with longitudinal and spiral seams,

• possibility of bending insulated steel pipes without damaging the insulation,

• possibility of joining insulated steel pipes without damaging the insulation,

• neutrality of the insulation in relation to the natural environment.

The developed application technology allows to obtain a three-layer anti-corrosion polyethylene or polypropylene coating on the pipe, consisting of:

• epoxy layers with a minimum thickness of 60 μm / 125 μm (depending on the standard of execution),

• copolymer (bonding agent), 140 μm / 150 μm (depending on the standard of execution),

• polyethylene or polypropylene layers from 1.8mm to 4.7mm.